Tank Inspection & Management

Providing Comprehensive Inspections, Non-destructive Testing and Cleaning Services while storage tanks & cooling towers remain full and in-service

Request a Quote

Online Inspection & Cleaning

No Downtime

No Scaffolding

Increased Safety

Fewer People on Location

Improved Efficiency

No Man Entry into Confined Space

Our team includes inspectors with the following CERTIFICATIONS:

- ASME Tank inspections and Reporting

- NFPA 25 - Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems

- API 510 Pressure Vessels: In-service inspection and reporting

- API 570 Piping Systems: In-service Inspection and Reporting

- API 653 Tanks - Steel, Fiberglass, and Polymer: Internal & External Inspection and Reporting

- STI SP001 Steel Tank Institute Inspections and ReportingNew Paragraph

Interior Inspections

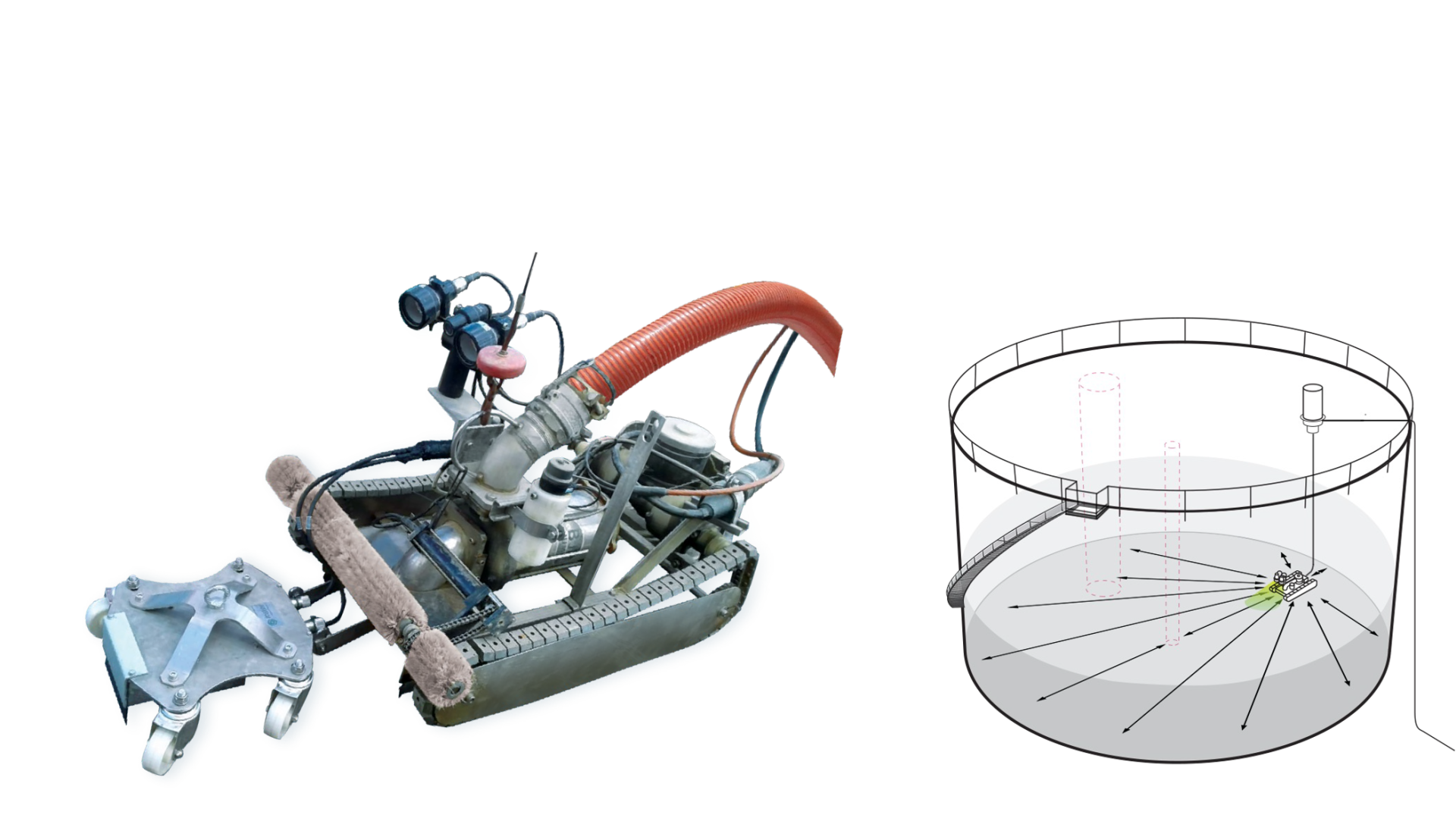

DT ROBOTIC INSPECTION SERVICES that are designed to perform ultrasonic-thickness (U/T) testing on the floors of Fuel Storage Tanks (e.g., JP-8 jet fuel, Diesel, etc.) while they remain FULL (No draining) and In-Service.

Interior Inspections

Our process includes using our REMOTE OPERATED VEHICLES (ROVs) to perform an internal survey of your tank or water containment system to evaluate the metal integrity of the tank floor using NDT methods and determine whether sedimentation and sludge cleaning are required.

The inspection survey is specifically designed to video your tank while it remains in service (Full with NO Draining Required).

The survey will provide feedback on the tank’s interior coating, roof, and all the internal structural items (e.g., ladders, influent/effluent piping, over-flow, drains) to evaluate any corrosion as well as identify the level of sedimentation that has accumulated on the tank floor.

SAFE Our service teams are trained to utilize our ROVs to deliver high-quality inspections and cleaning services in confined areas and conditions that are unsuitable for man.

EFFICIENT Our uniquely designed machines allow us to perform inspection and cleaning services while your storage containment remains completely operational.

Exterior Inspections

API INSPECTIONS AND NON-DESTRUCTIVE TESTING

We provide assistance with a comprehensive mechanical integrity plan to protect your equipment. Our team of API-certified inspectors and support personnel will inspect your pressure vessels, tanks, and associated piping and provide detailed reports and recommendations for your review.

STEEL TANK INSTITUTE (STI) INSPECTIONS

One of our Certified Inspectors will provide a thorough inspection based on the criteria identified by The Steel Tank Institute (STI) Standard for the Inspection of Aboveground Storage Tanks, SP001, in order to determine the suitability for continued service of aboveground storage tanks (AST) until the next scheduled inspection.

VISUAL INSPECTIONS

A complete visual inspection allows our team to verify the condition of each piece of equipment. Areas inspected include the foundation, anchoring, protective coating, vibration, and signs of external corrosion.

Our capabilities include Inspection and Cleaning Services for:

Power and Energy Industries

Condensate Storage Tanks

Cooling Towers

Lined Service Water Basins

Radioactive and Non-radioactive Ponds

Fire Suppression Tanks

Demineralized Water Tanks Water Industry

Storage Tanks

Clear Wells

Petroleum and Chemical Industries

Jet-Fuel Tanks (JP-8)

Diesel Storage Tanks

Fire Suppression Tanks

Chemical Storage Tanks

Fuel Storage Vessels

Process Storage Tanks

Water Tank Cleaning & Inspection

■ Depth up to 490 ft

■ Ultrasonic thickness measuring device

■ Gripper for up to 88 lbs

■ High Resolution Camera

■ Sonar engaged for bathymetry

Bottom of Tank Plate Inspection

• Ultrasonic inspection of tank bottom;

• No work in confined space

• No downtime

• Tank remains in operation

• Inspection according to API 653